ZB1450CT-550SA

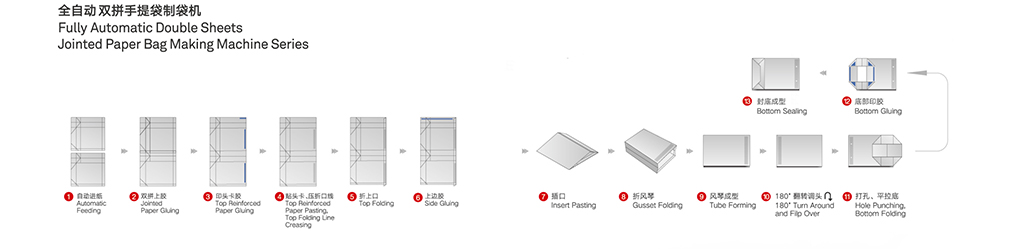

Fully Automatic Double Sheets Jointed Paper Bag Making Machine

This machines has double feeders feeding,and is the first time in the world to realize the double-sheet paper bag process.

This series machine can produce wide-width paper bags from narrow-width paper,solving the problems of users with small-width printing machines and saving users investment in printing machines and various paper processing equipment before bag making . It can also be used as a sinle-sheet feed paper bag machine , with two uses in one machine , saving users investment in paper bag machines.

This adopts automatic top reinforced cardboard pasting and top folding ( inserting pasting ) , and In customize the 4pcs top reinforce cardboard function to meet the production needs of various luxury bags and high-quality boutique bags .CT series has served many first-tier famous brands and is sold to European and American developed countries such as Germany , Italy and the United States , as well as developing countries such as South America and Southeast Asia , with annual sales exceeding 100 unitsIf you are a manufacturer of luxury paper bags and boutique paper bags , but are limited by arrow-format printing machines , this series is your ideal choice.

(▲You can click the picture see the machine work flow in youtube)

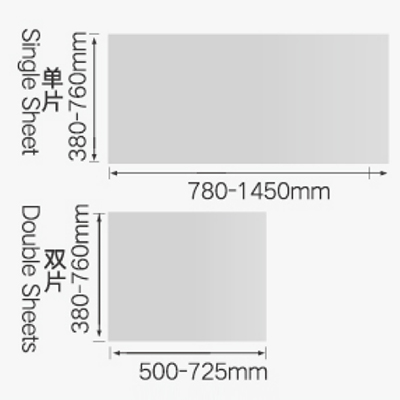

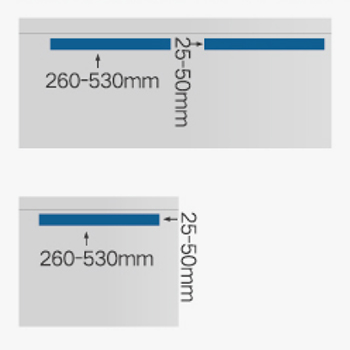

The glue position is on the big side (bag surface)

Automatic Top Folding

|

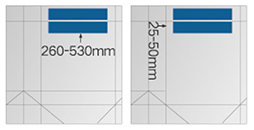

Max.One Sheet (L* W) |

1450 x760mm |

|

Min.One Sheet (L* W) |

780 x 380mm |

|

Sheet weight |

190-250g/㎡ |

|

Top folding width |

30-60mm |

|

Paper Bag Tube Length |

350-720mm |

|

Bottom Width(B) |

100-240mm |

|

Bag Width |

280-550mm |

|

Top Reinforce Cardboard Weight |

200-500g/㎡ |

|

Top Reinforce Cardboard Length |

260-530mm |

|

Top Reinforce Cardboard Width |

25-50mm |

|

Bottom Cardboard Weight |

-- |

|

Bottom Cardboard Width |

-- |

|

Bottom Cardboard Length |

-- |

|

Speed |

25-50 bags/min |

|

Machine Size |

26500*6100*1800mm |

|

Total/Production Power |

48/28.8kw |

|

Voltage |

380V |

|

Total Weight |

23.5T |

|

Glue Type |

Water Base Glue And Hot-melt Glue |

| No. | Name | Origin | Brand | No. | Name | Origin | Brand |

| 1 | Feeder | China | RUN | 12 | Bearing | Germany | BEM |

| 2 | Main motor | China | Fangda | 13 | Belt | Japan | NITTA |

| 3 | PLC | Japan | Mitsubishi | 14 | Synchronize belt | Germany | Continental |

| 4 | Frequency converter | France | Schneider | 15 | Air pump | Germany | Becker |

| 5 | Button | Germany |

Eaton Moller |

16 | Pneumatic component | Taiwan/Japan | Airtac/SMC |

| 6 | Electric relay | Germany | Weidmuller | 17 | Pilot valve | Taiwan/Japan | Airtac/SMC |

| 7 | Air switch | Germany |

Eaton Moller |

18 | Photoelectric switch | Korea/Germany | Autonics/Sick |

| 8 | AC contactor | Germany |

Eaton Moller |

19 | Hot melt glue system | America | Nordson |

| 9 | Wiring terminal | Germany | Weidmuller | 20 | Servo motor | Taiwan | Delta |

| 10 | Touch screen | Taiwan | Weinview | 21 | Servo gear box | Japan | Desboer |

| 11 | Switching Power Supply | Taiwan | MW |

By continuing to use the site you agree to our privacy policy Terms and Conditions.