ZB 1260S-450

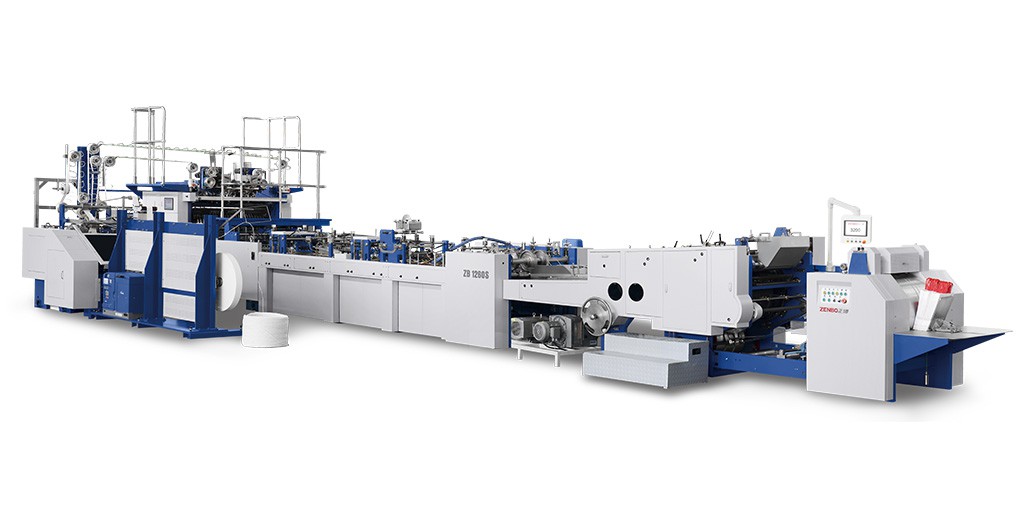

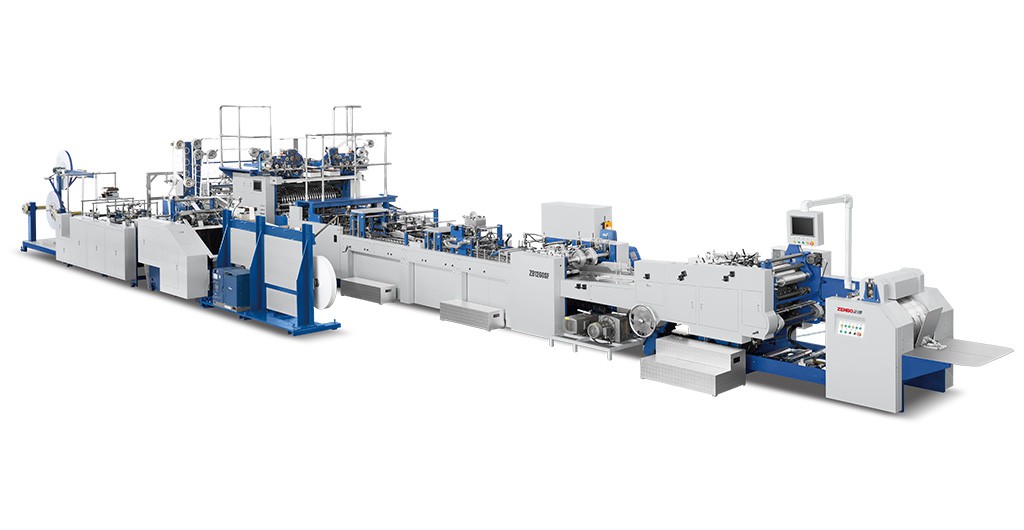

Fully Automatic Sheet-feeding Paper Bag Making Machine

Brand new ZB1100S-380 Fully automatic sheet feeding paper bag making machine (independent innovation) is suitable for the production of Eco-friendly paper shopping bags with twisted rope handles in line.

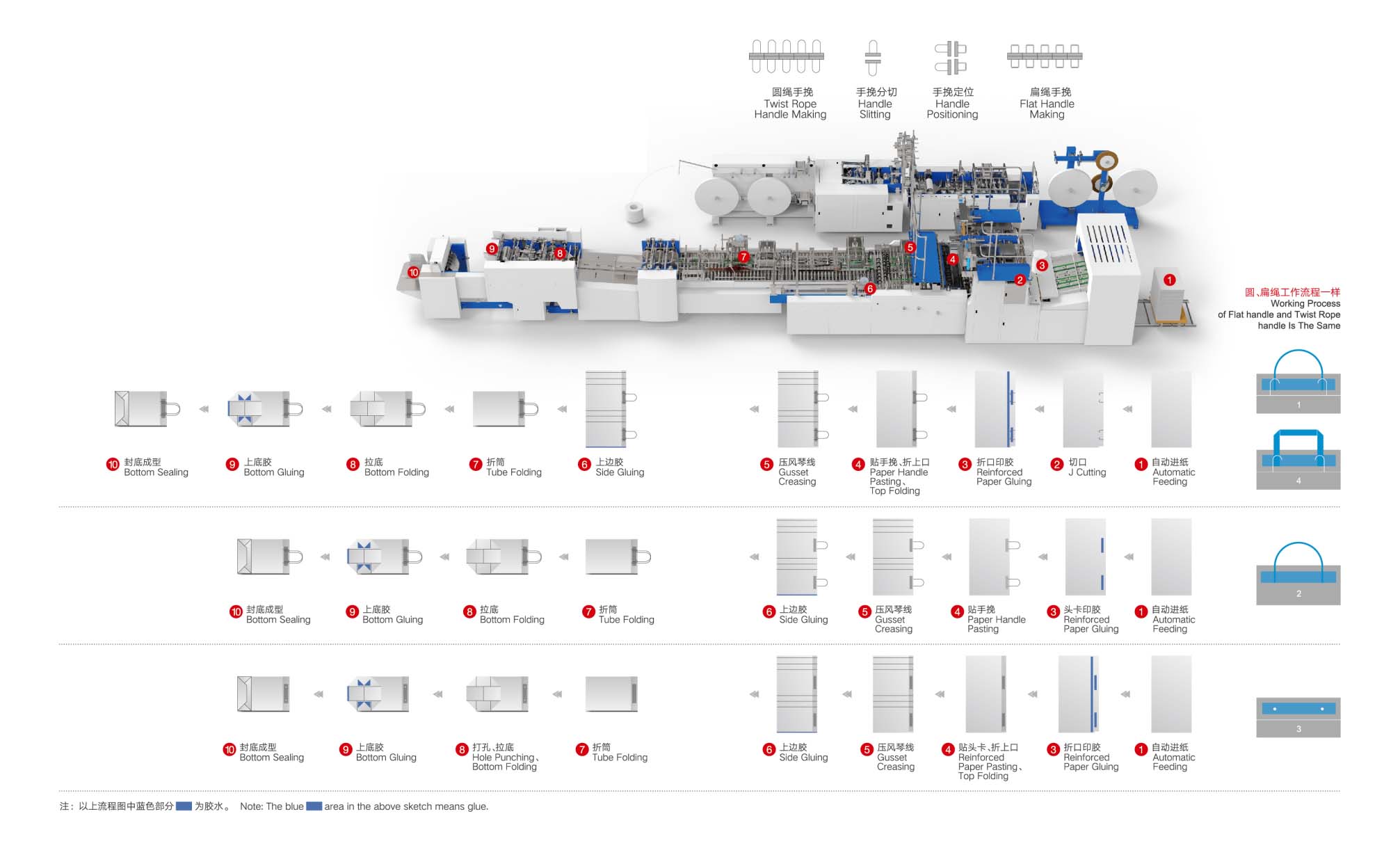

This machine adopts single sheet as feeding way, the handle making unit use Reinforce Paper Roll and Paper Twist rope as raw material to make Paper handle in line. Through servo delivery the handle, servo cutting and positioning, automatically paste the paper handle on the inside of the bag mouth, and then automatically top folding(directly pasting), automatic creasing, tube forming, gusset forming, square bottom open, bottom gluing、bottom pasting, compaction output.

This machine equips advanced compact servo handle cut-off system to replace the traditional complex mechanical structure, which reduced the setup time. The bag making machine and handle making unit have separate servo control systems to avoid the handle waste.

(▲You can click the picture see the machine work flow in youtube)

Gluing Position On Big Side (Bag Surface)

Gluing Position On Small Side (Bag Surface)

Card Cutting System

|

|

|

|

|

| Max Sheet(L*W) | 1100*600mm | 1100*560mm | 1100*600mm |

| Min Sheet(L*W) | 520*320mm | 520*320mm | 520*320mm |

| Paper Weight | 120-190gsm | 120-190gsm | 120-190gsm |

| Bag Width | 180-380mm | 180-380mm | 180-380mm |

| Bottom Width | 70-170mm | 70-170mm | 70-170mm |

| Bag Tube length | 280-560mm | 320-560mm | 280-560mm |

| Top folding width | 40-60mm | - | 40-60mm |

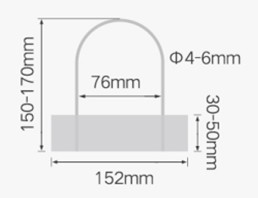

| Handle patch length | 152mm | 152mm | 152mm |

| Handle patch width | 30-50mm | 30-50mm | 30-50mm |

| Handle patch weight | 120-190gsm | 120-190gsm | 120-190gsm |

| Handle patch roll diameter | Φ1000mm | Φ1000mm | Φ1000mm |

| Handle patch roll width | 60-100mm | 60-100mm | 60-100mm |

| Paper rope diameter | Φ4-6mm | Φ4-6mm | - |

| Handle rope height | 150-170mm | 150-170mm | - |

| Speed | 40-70bags/min | ||

| Total/Production power | 35.7/21.4kw | ||

| Voltage | 380V | ||

| Total weight | 22 T | ||

| Machine size(L x W x H) | 17100*5600*2950mm | ||

| Glue Type | Water Base Glue And Hot-melt Glue | ||

| No. | Item | Origin | Brand | No. | Item | Origin | Brand |

| 1 | Feeder | China | RUN | 9 | Main Bearings | Germany | BEM |

| 2 | Motor | China | Fangda | 10 | Convey Belt | Japan | NITTA |

| 3 | PLC | Japan | Mitsubishi | 11 | Vaccum Pump | Germany | BECKER |

| 4 | Frequency Converter | France | Schneider | 12 | Pneumatic Elements | Taiwan China | AIRTAC |

| 5 | Button | Germany | Eaton Moller | 13 | Photoelectric Sensor | Korea/Germany | Autonics/SICK |

| 6 | Electric Relay | Germany | Weid Muller | 14 | Glue system | Amercia | Nordson |

| 7 | Air Switch | Germany | Eaton Moller | 15 | Reducer | China | Wuma |

| 8 | Touch Screen | Taiwan China | WEINVIEW | 16 | Servo Motor | Taiwan China | Delta |

Fully Automatic Sheet-feeding Paper Bag Making Machine

Fully Automatic Sheet-feeding Paper Bag Making Machine

Fully Automatic Sheet-feeding Paper Bag Making Machine

Fully Automatic Sheet-feeding Paper Bag Making Machine

Fully Automatic Paper Bag Making Machine

By continuing to use the site you agree to our privacy policy Terms and Conditions.