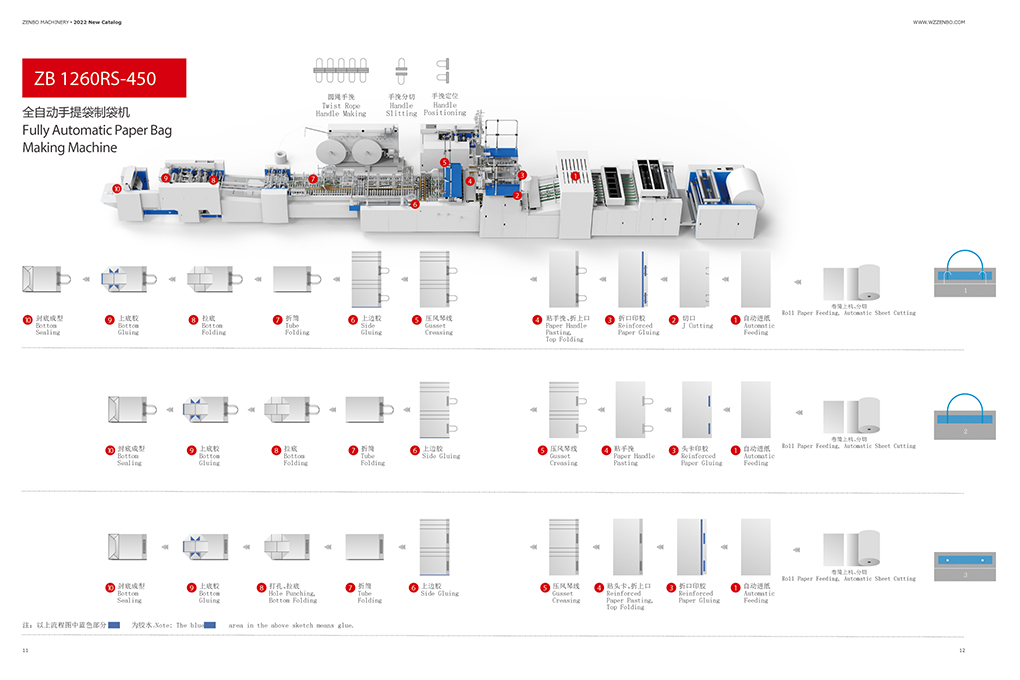

ZB 1260S-450

Fully Automatic Sheet-feeding Paper Bag Making Machine

This series of machines equipped with a high-precision servo drive rotary blade sheeting unit,and customers can directly use printed roll paper as raw material to feed into the machine. ,reduces the number of times of paper loading and paper change downtime,reduces the number of operators and reduces labour intensity.

The T series uses the roll feeding method with top folding craft. It reduces the frequency of paper specification changing and the downtime of the machine, The speed is twice that of the traditional models.

Two handle patch size can be changed in 30 minutes, this solves the dilemma of users in choosing machines due to the diversification of producion orders, compared to traditional paper bag machines, this innovative model can save 6-8kg of handle raw material per day by using full servo-controlled handle cutting, decreasing the investment cost while maintaining high efficiency, achieving the maximum economic efficiency.

The whole machine is equipped with power servos, and some units are configured with adjustable servos, which reduces the difficulty of machine adiustment, saves time, and improves production stability, The intelligent full-servo (Model E) function of the whole machine can be customized, largely shortening the size changing time, and assisting in the fully automatic production industry challenge of diverse paper bags with small order quantities, creating more market value for users.

This seres is an ideal choice for efficient bag making.

Gluing Position On Big Side (Bag Surface)

Can Be Customized

|

T130 |

|

|

|

| Paper Roll Width | 450-770mm | 450-770mm | 450-770mm |

| Slitting Length | 265-445mm | 225-405mm | 265-445mm |

| Max Roll Diameter/weight | Φ1200mm/1200kg | Φ1000mm/1000kg | Φ1000mm/1000kg |

| Paper Core Diameter | Φ76mm | Φ76mm | Φ76mm |

| Sheet Weight | 100-190gsm | 100-190gsm | 100-190gsm |

| Bag Width | 125-260mm | 125-260mm | 125-260mm |

| Bottom Width | 60-130mm | 60-130mm | 60-130mm |

| Bag Tube Length | 225-405mm | 225-405mm | 225-405mm |

| Top Folding Depth | 40-50mm | - | 40-50mm |

| Handle Patch Length | 132mm/114mm | 132mm/114mm | 132mm/114mm |

| Handle Patch Width | 30-50mm/(30-40mm) | 30-50mm/(30-40mm) | 30-50mm/(30-40mm) |

| Handle Patch Weight | 120-190gsm | 120-190gsm | 120-200gsm |

| Handle Patch Roll Diameter | Φ1000mm | Φ1000mm | Φ1000mm |

| Handle Patch Roll Width | 60-80mm | 60-80mm | 60-80mm |

| Paper Rope Diameter | Φ4-6mm | Φ4-6mm | - |

| Handle Rope Height | 150-160mm/(80-100mm) | 150-160mm/(80-100mm) | - |

| Speed | 70-120bags/min | ||

| Total/Production Power | 57.5/34.5KW | ||

| Voltage | 380V | ||

| Total Weight | 25.3T | ||

| Machine Size(LXWXH) | 18500*6100*2950mm | ||

| Glue Type | Water Base Glue And Hot-melt Glue | ||

| No. | Item | Origin | Brand | No. | Item | Origin | Brand |

| 1 | Feeder | China | RUN | 9 | Main Bearings | Germany | BEM |

| 2 | Motor | China | Fangda | 10 | Convey Belt | Japan | NITTA |

| 3 | PLC | Japan | Mitsubishi | 11 | Vaccum Pump | Germany | BECKER |

| 4 | Frequency Converter | France | Schneider | 12 | Pneumatic Elements | Taiwan China | AIRTAC |

| 5 | Button | Germany | Eaton Moller | 13 | Photoelectric Sensor | Korea/Germany | Autonics/SICK |

| 6 | Electric Relay | Germany | Weid Muller | 14 | Glue system | Amercia | Nordson |

| 7 | Air Switch | Germany | Eaton Moller | 15 | Reducer | China | Wuma |

| 8 | Touch Screen | Taiwan China | WEINVIEW | 16 | Servo Motor | Taiwan China | Delta |

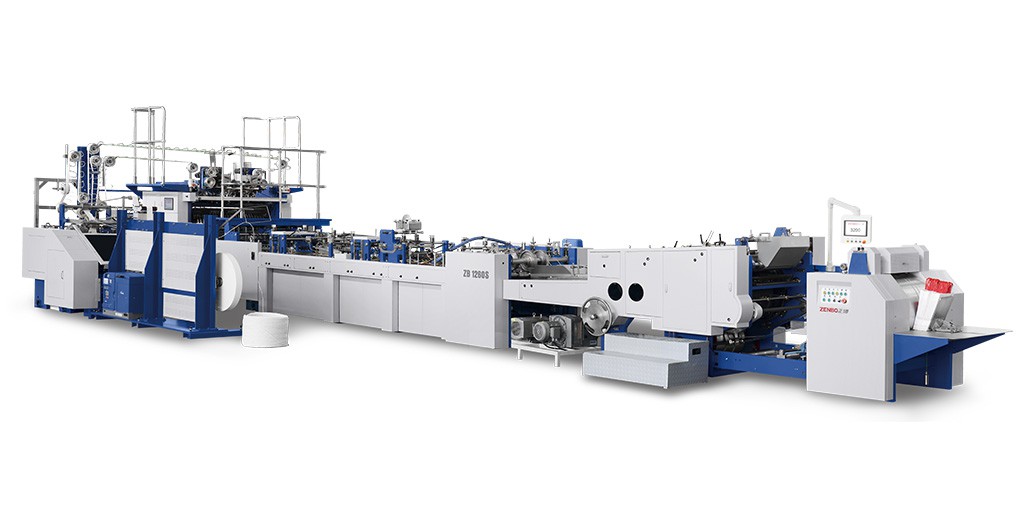

Fully Automatic Sheet-feeding Paper Bag Making Machine

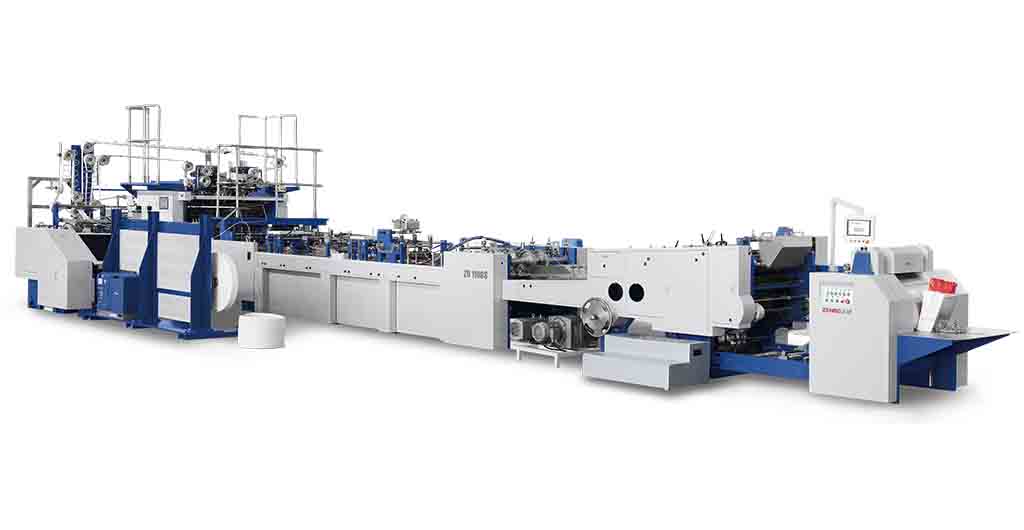

Fully Automatic Sheet-feeding Paper Bag Making Machine

Fully Automatic Sheet-feeding Paper Bag Making Machine

Fully Automatic Paper Bag Making Machine

Fully Automatic Paper Bag Making Machine

Fully Automatic Paper Bag Making Machine

By continuing to use the site you agree to our privacy policy Terms and Conditions.