Comparison

The product has been added to the "compare" list. You can choose up to 2 items for comparison.

This series of machines can be used in both roll and sheet feeding methods to meet the different printed papers. it is an easy change feeding method by button switch.

Learn More >

This series of machines main produce paper bag with round or flat handle ,and adopt full servo handle slitting,which saves 6-8kg of handle raw material in a single day than traditional paper bag making machine.

Learn More >

This series of machines adopts roll feeding method , mainly used for the production of eco-friendly paper bag with or without handles,standard configuration fixed point humidification function(Prevent paper from cracking due to over-drying during machine production).

Learn More >

This series of machines adopts sheet feeding paper, mainly used for the production of boutique or luxury paper bags,suitable art paper、special paper、lvory board paper、etc.

Learn More >

This series of machines can produce wide-width paper bags from narrow-width paper, solving the problems of users with small-width printing machines and saving users’ investments in printing machines and various paper processing equipment before bag making . It can also be used as a single-sheet paper bag machine, with two uses in one machine, saving users’ investments in paper bag machines.

Learn More >

This series of machines can realize the modular combination of square/split bottom in a single machine. One machine can realize two bottom processes to better meet the diverse production needs of users.

Learn More >

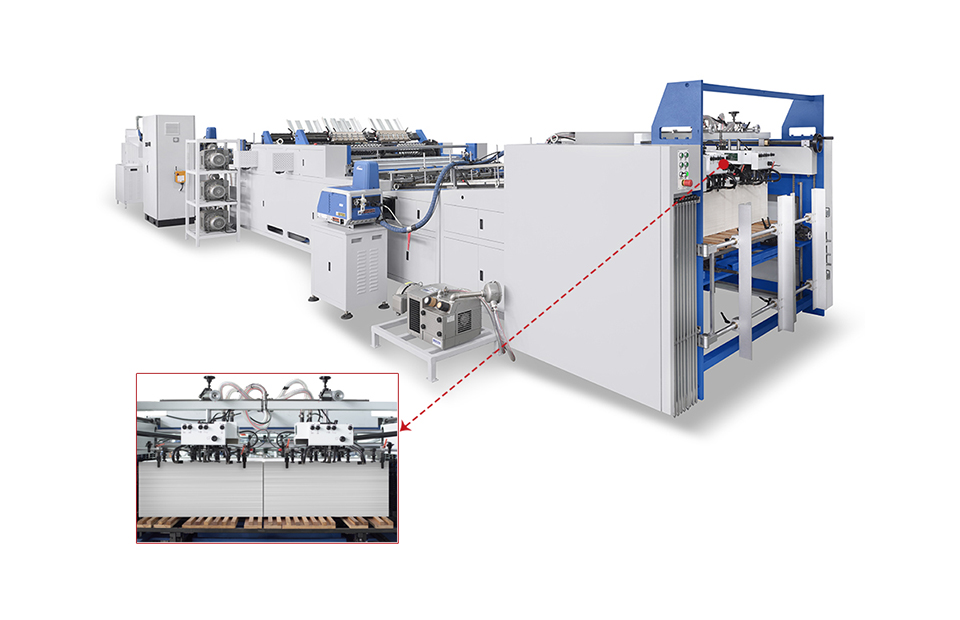

This series of machines adopts sheet feeding paper, uses “non-stop” insert bottom cardboard function. The maximum speed of the machine to make paper bags can be stabilized at 6000 per hour. And the range of sheet paper weight is between 190gsm-300gsm.

Learn More >By continuing to use the site you agree to our privacy policy Terms and Conditions.