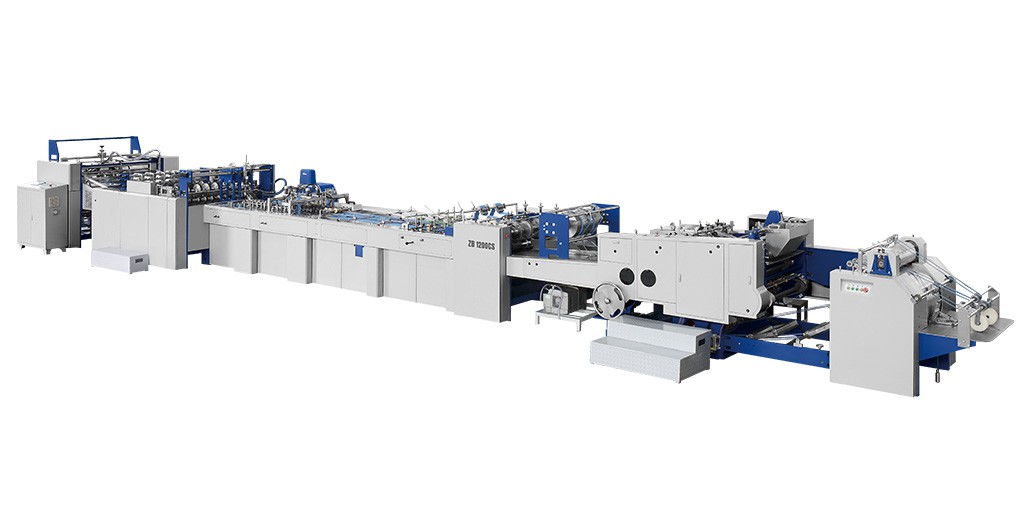

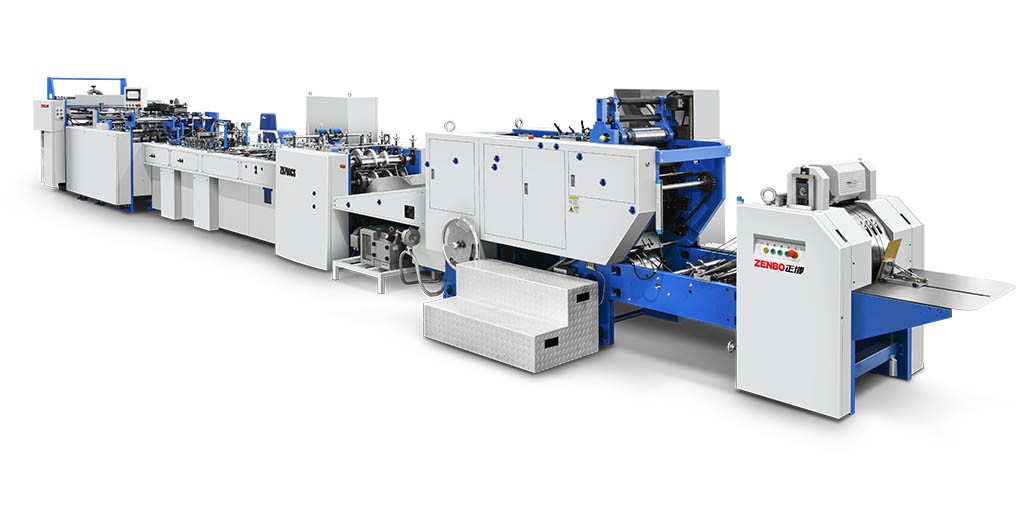

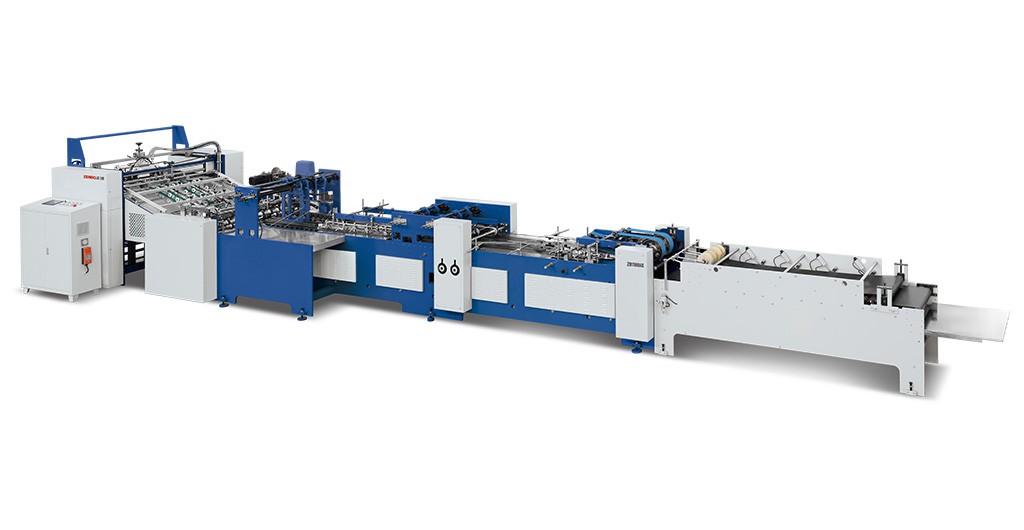

ZB 1200CS-430

Automatic Sheet-feeding Paper Bag Making Machine

CS series of machines is Zenbo invented advanced functions such as pull-down cam clamping and flipping, automatic top folding (insert pasting),automatic bottom cardboard inserting, and comprehensively applied these functions to launch this eqvipment, realizing a revolutionary trans"formation of gift paper bags from manual, semi-automatic to fully automatic production,and increasing the production efficiency of paper bags by more than 100%,This adopts a variety of leading technologies and processes invented by Zenbo, and has a high level of market value preservation,This is mainly used to produce heavy duty thing paper bags for tobacco, alcohol,milk products, beverages, etc,lt has served many first-line well-known brands of gift bags, with a cumulative sales of more than 500 sets.If you are a manufacturer of gift bags, have strict reguirements for paper bag cuality, and hope to achieve higher production efficiency, this seriesis your ideal choice.

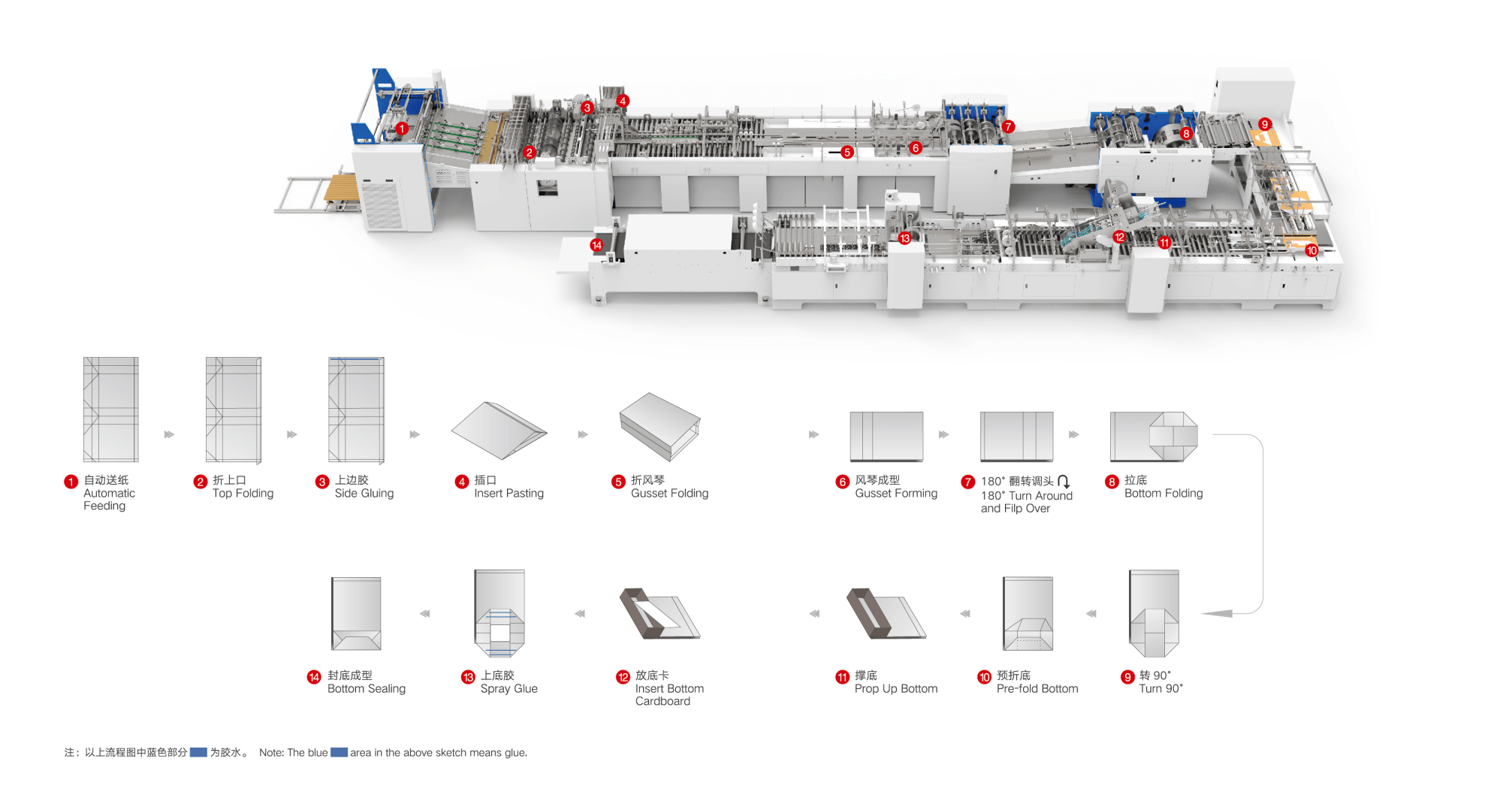

The basic working flow is sheet feeding, positioning, top folding (insert pasting), tube forming, gusset forming, bottom open, servo bottom cardboard inserting(square bottom), bottom gluing, compaction and output.

All these steps increase the bag making efficiency and save a lot of labor cost, replace the traditional manually paper bag making way. Realize automation, intelligent and high efficiency production requirement, which achieve the leading level in the world.

(▲You can click the picture see the machine work flow in youtube)

Automatic Bottom Cardboard Inserting ( Square Bottom )

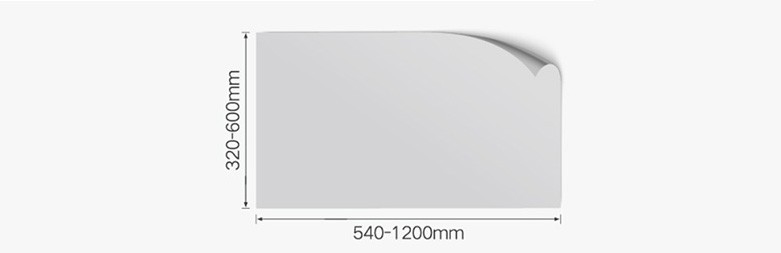

| ZB1200CS-430S | |

| Max.One Sheet(L*W) | 1200*600mm |

| Min.One Sheet(L*W) | 540*320mm |

| Paper Weight | 190-300gsm |

| Bag Width | 180-430mm |

| Bottom Width | 60-180mm |

| Bag Tube length | 280-570mm |

| Top Folding Depth | 30-70mm |

| Bottom Cardboard Weight | 250-400gsm |

| Bottom Cardboard Width | 50-170mm |

| Bottom Cardboard Length | 170-420mm |

| Production Speed | 60-120bags/min |

| Total/Production power | 35.7/21.4KW |

| Voltage | 380V |

| Total weight | 16.5T |

| Machine size(L x W x H) | 14400*4900*1800mm |

| Glue Type | Water Base Glue and Hot-melt Glue |

| No. | Item | Origin | Brand | No. | Item | Origin | Brand |

| 1 | Feeder | China | RUN | 8 | Main Bearings | Germany | BEM |

| 2 | Motor | China | Fangda | 9 | Convey Belt | Japan | NITTA |

| 3 | PLC | Japan | Mitsubishi | 10 | Touch Screen | Taiwan China | WEINVIEW |

| 4 | Frequency Converter | France | Schneider | 11 | Vaccum Pump | Germany | BECKER |

| 5 | Button | Germany | Eaton Moller | 12 | Pneumatic Elements | Taiwan China | AIRTAC |

| 6 | Electric Relay | Germany | Weidmuller | 13 | Photoelectric Sensor | Korea/Germany | Autonics/SICK |

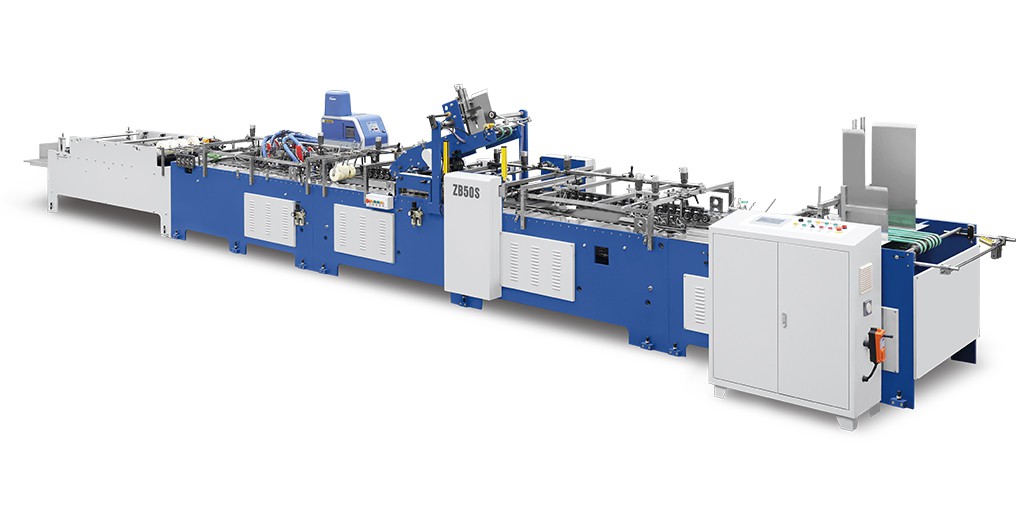

Automatic Sheet-feeding Paper Bag Making Machine

Sheet-feeding Paper Bag Bottom Gluing Machine

Automatic Sheet-feeding Paper Bag Making Machine

Sheet-feeding BagTube Forming Machine

Hand Bag Bottom Gluing Machine

Sheet-feeding Paper Bag Bottom Gluing Machine

By continuing to use the site you agree to our privacy policy Terms and Conditions.